Our Products

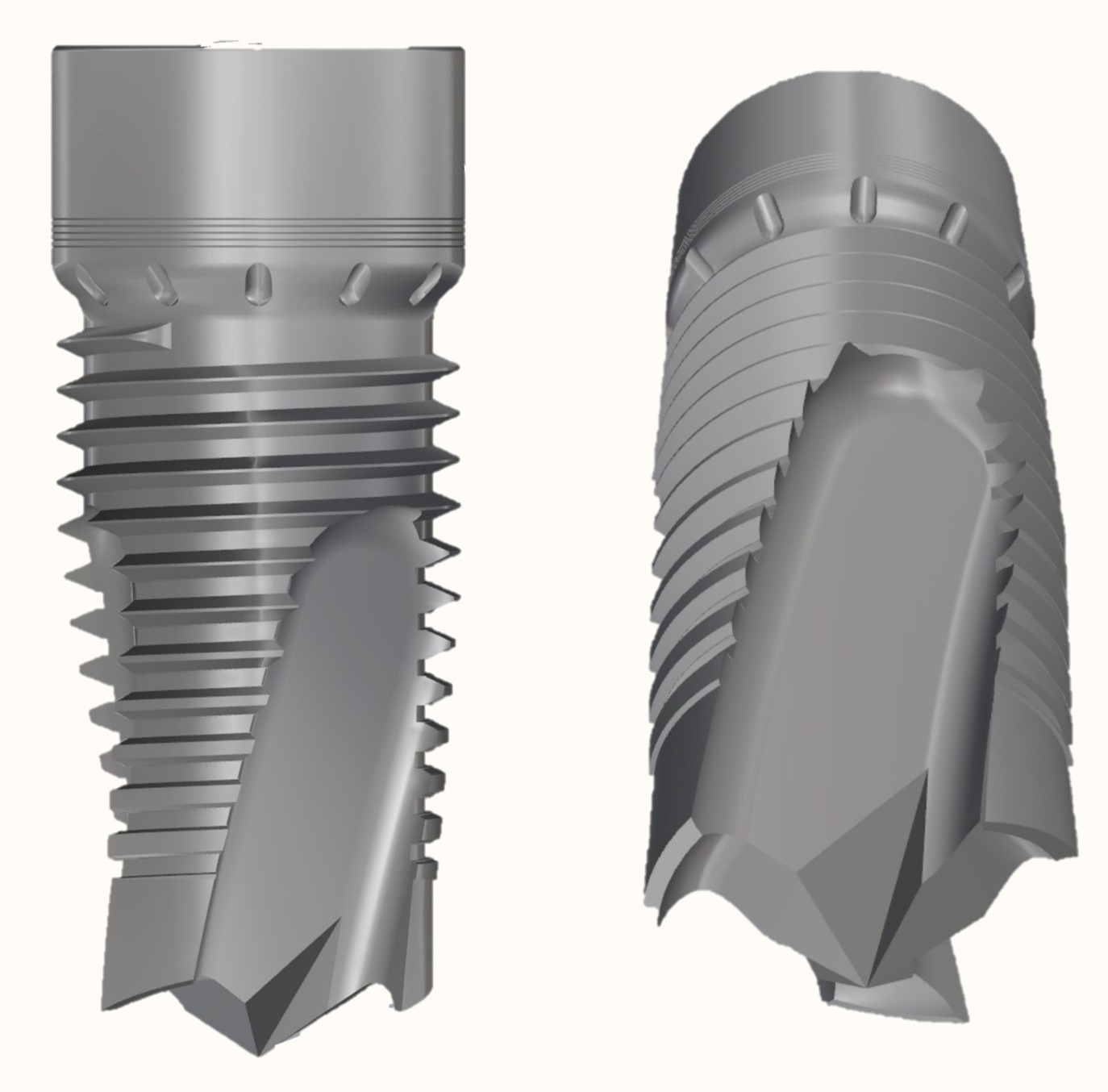

Dental Implants

• Simple Inventory:

Small Ø 3.5 (L 9,11,13)

Medium Ø 4.5 (L 9,11,13)

Large Ø 5.5 (L 7,9,11)

• Flap or flapless surgeries

• Centering tip

• Self-inserting

• Gingival knives

• Bone reservoirs

• Precise fit without bone pressure

• Rough surface texture

• Collar: polished occlusal 1/3

Dental Implants

• Simple Inventory:

Small Ø 3.5 (L 9,11,13)

Medium Ø 4.5 (L 9,11,13)

Large Ø 5.5 (L 7,9,11)

• Flap or flapless surgeries

• Centering tip

• Self-inserting

• Gingival knives

• Bone reservoirs

• Precise fit without bone pressure

• Rough surface texture

• Collar: polished occlusal 1/3

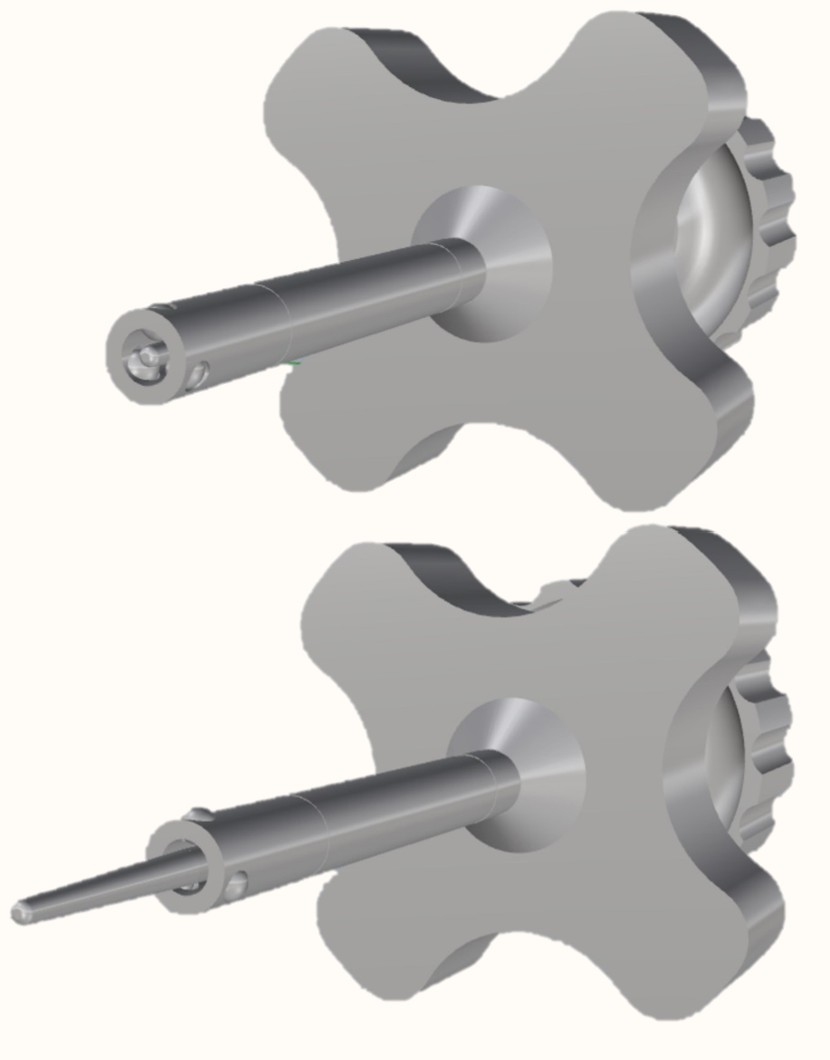

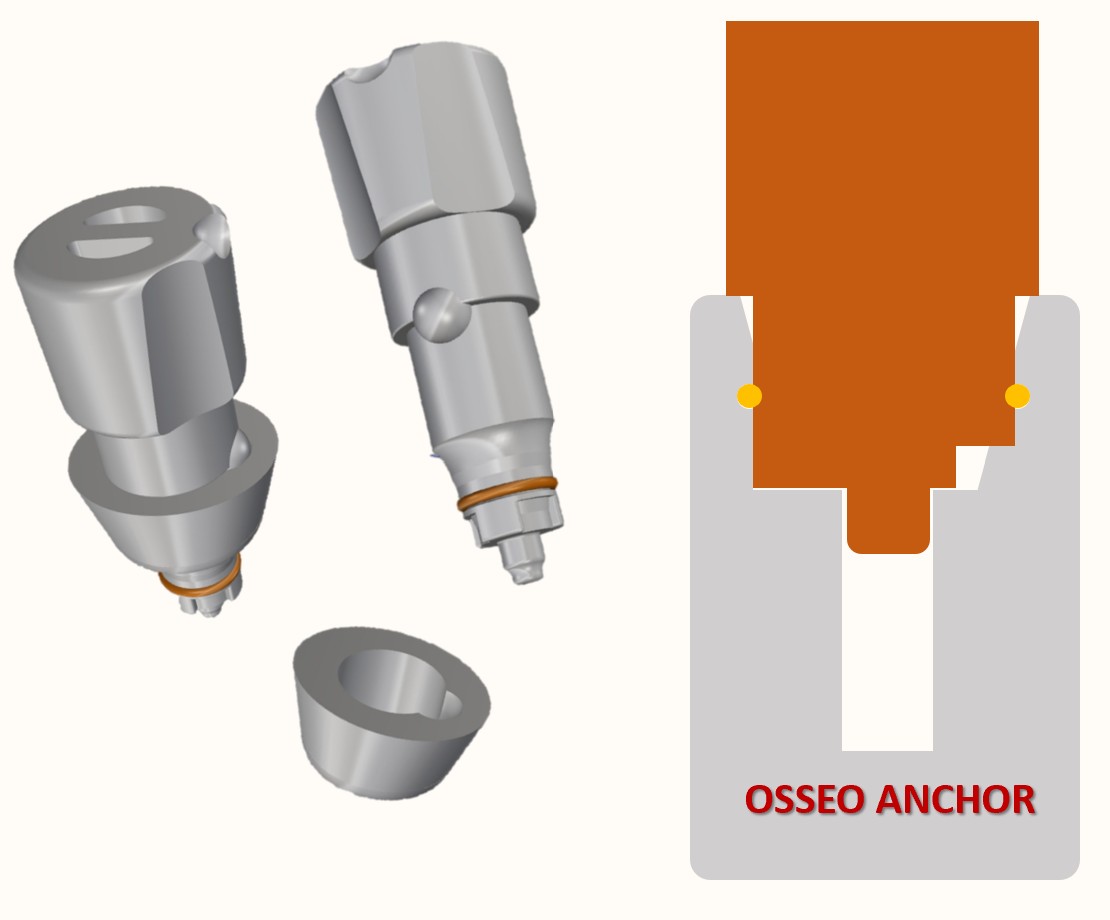

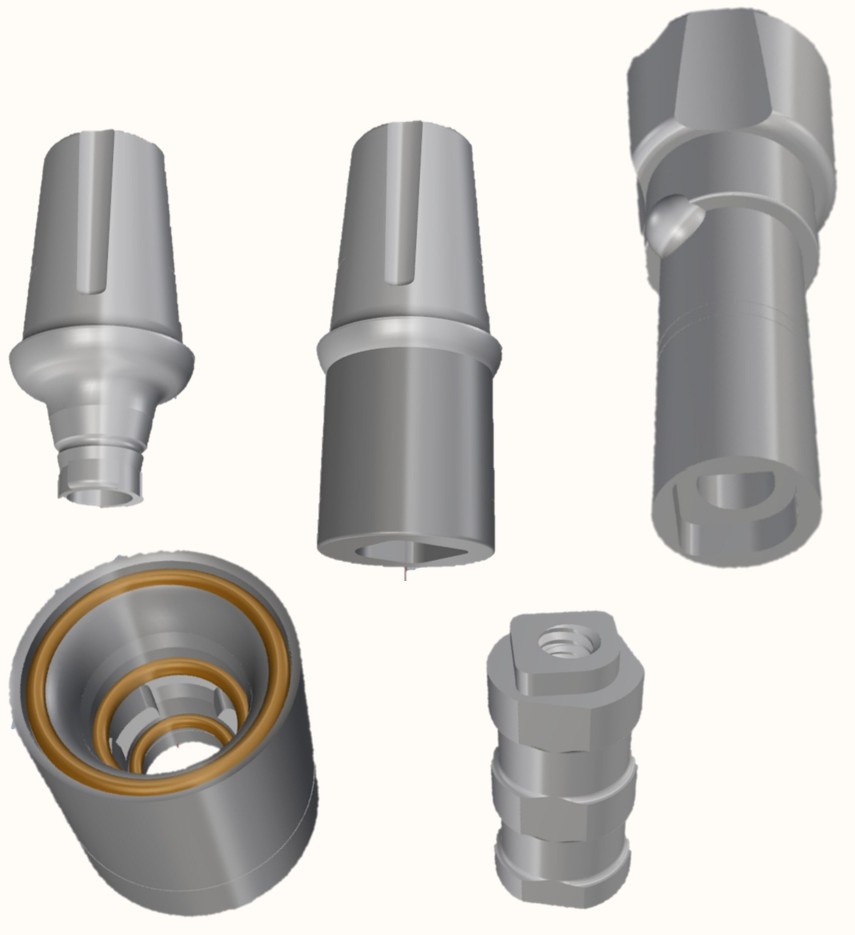

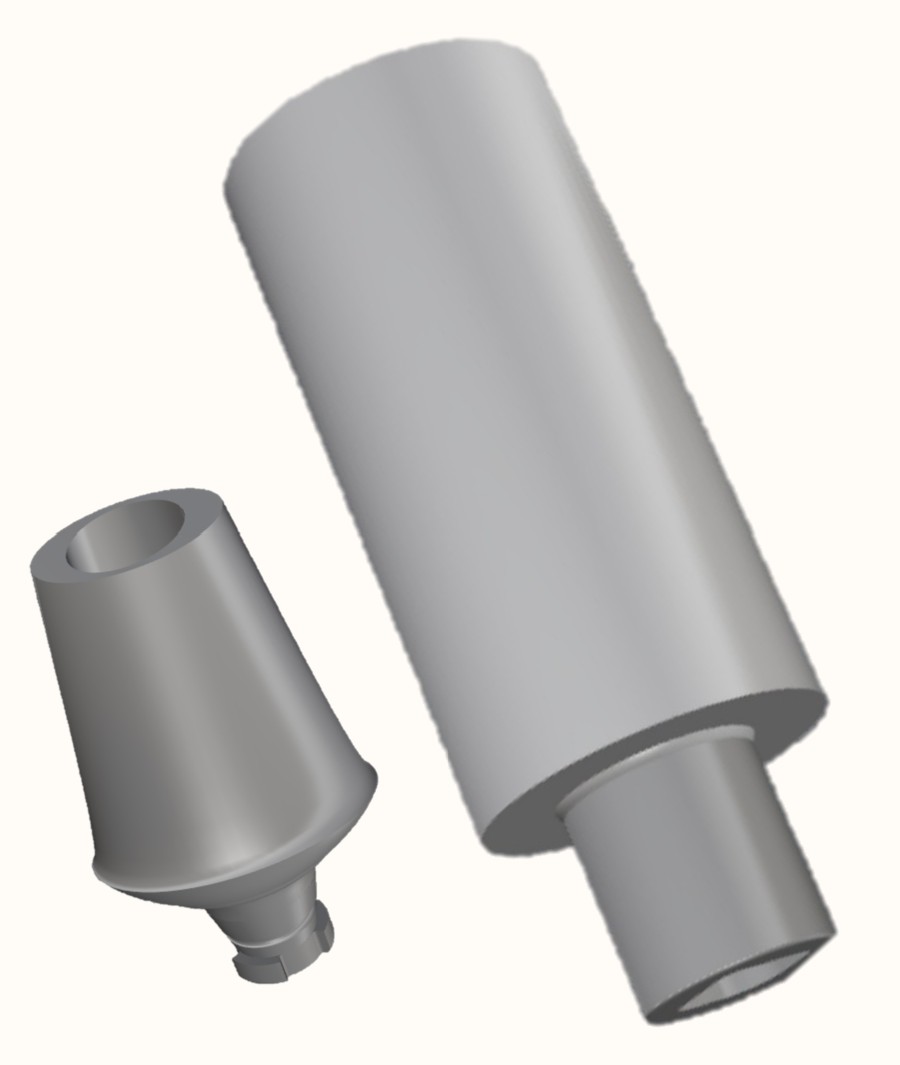

Implant Driver

• Does not engage the prosthetic interface.

• No drop feature with O-ring retention.

• Snaps in and out of the implant.

• Does not engage the prosthetic interface.

• No drop feature with O-ring retention.

• Snaps in and out of the implant.

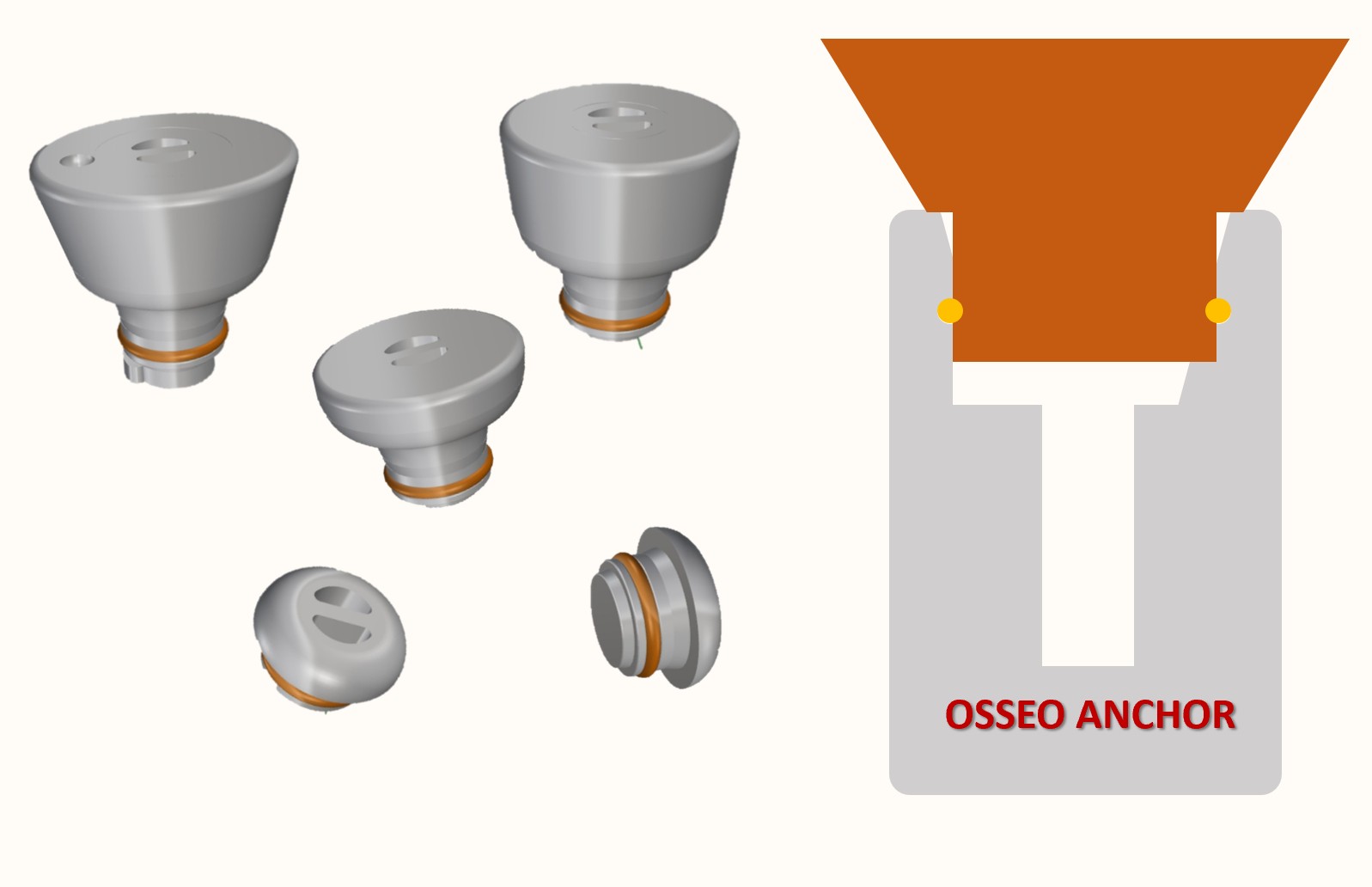

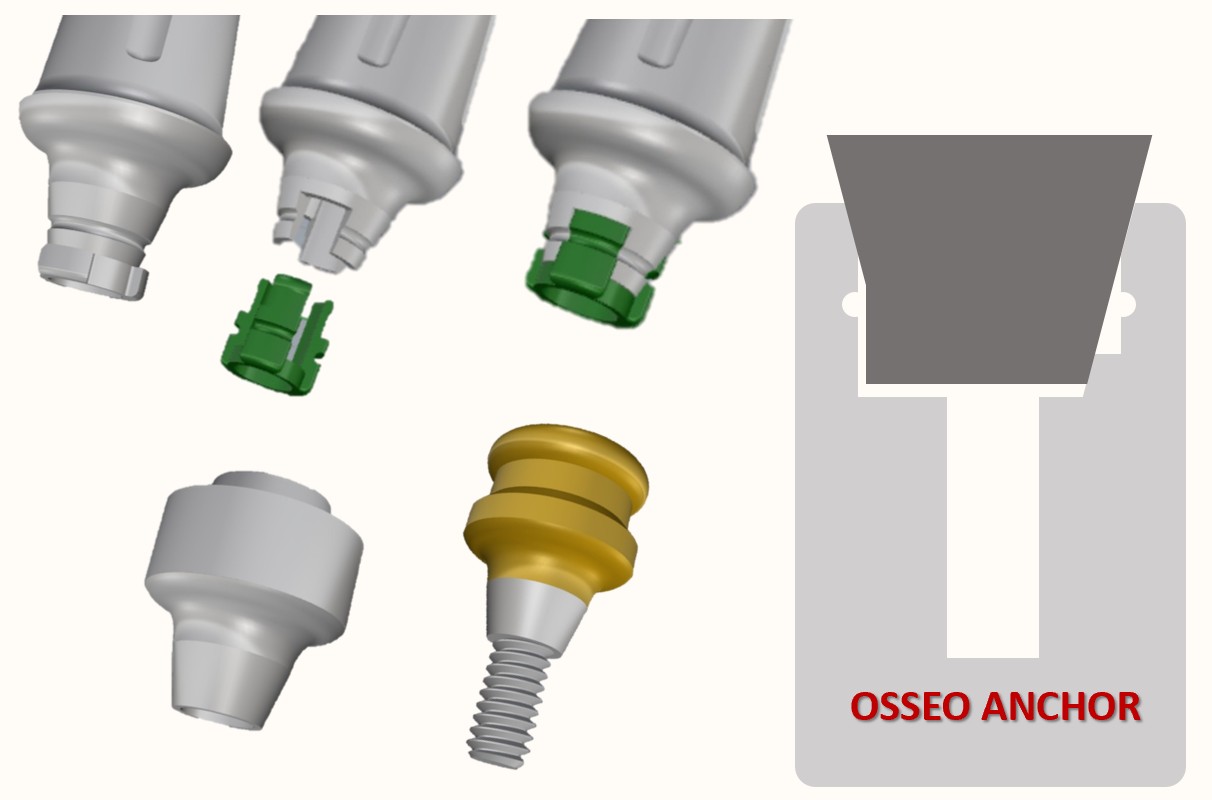

Temporary Abutments

• Made of biocompatible PEEK resin.

• Does not engage the prosthetic interface.

• Retained by O-ring.

• Handling with a cotton plier.

• Made of biocompatible PEEK resin.

• Does not engage the prosthetic interface.

• Retained by O-ring.

• Handling with a cotton plier.

Scanning and Impression Post

• Made of biocompatible PEEK resin.

• Does not engage the prosthetic interface.

• Retained by O-ring.

• Handling with cotton plier.

• For closed tray impression and optical scanning

• Made of biocompatible PEEK resin.

• Does not engage the prosthetic interface.

• Retained by O-ring.

• Handling with cotton plier.

• For closed tray impression and optical scanning

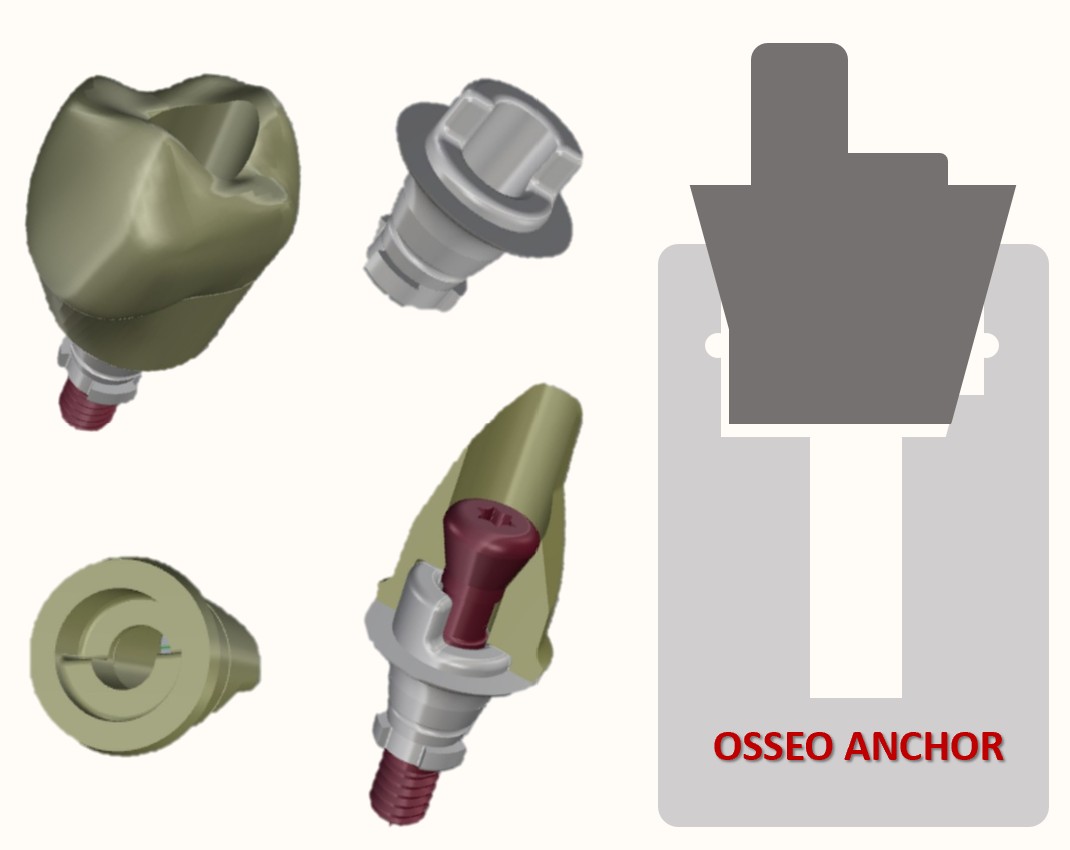

Titanium Abutments

• Made of titanium.

• Engages only once in the implant.

• Engaging or not.

• Flexible engagement.

• Multi-Unit compatible.

• One-piece Zest abutment.

• Made of titanium.

• Engages only once in the implant.

• Engaging or not.

• Flexible engagement.

• Multi-Unit compatible.

• One-piece Zest abutment.

Zirconia Components

• Titanium base.

• Crowns and abutments are milled in the lab.

• No glue between zirconia and base.

• The screw clamps the zirconia to the implant.

• Titanium base.

• Crowns and abutments are milled in the lab.

• No glue between zirconia and base.

• The screw clamps the zirconia to the implant.

Prosthetic Screws

• Made of titanium alloy.

• Stretchable zone for optimal pre-loading.

• Torx T5 screwdriver.

• Conical head for zirconia abutments/crowns.

• Square head for titanium abutments.

• Coated threads for Loctite effect.

• Delivered pre-lubricated.

• Always torqued at 35 Ncm.

• Made of titanium alloy.

• Stretchable zone for optimal pre-loading.

• Torx T5 screwdriver.

• Conical head for zirconia abutments/crowns.

• Square head for titanium abutments.

• Coated threads for Loctite effect.

• Delivered pre-lubricated.

• Always torqued at 35 Ncm.

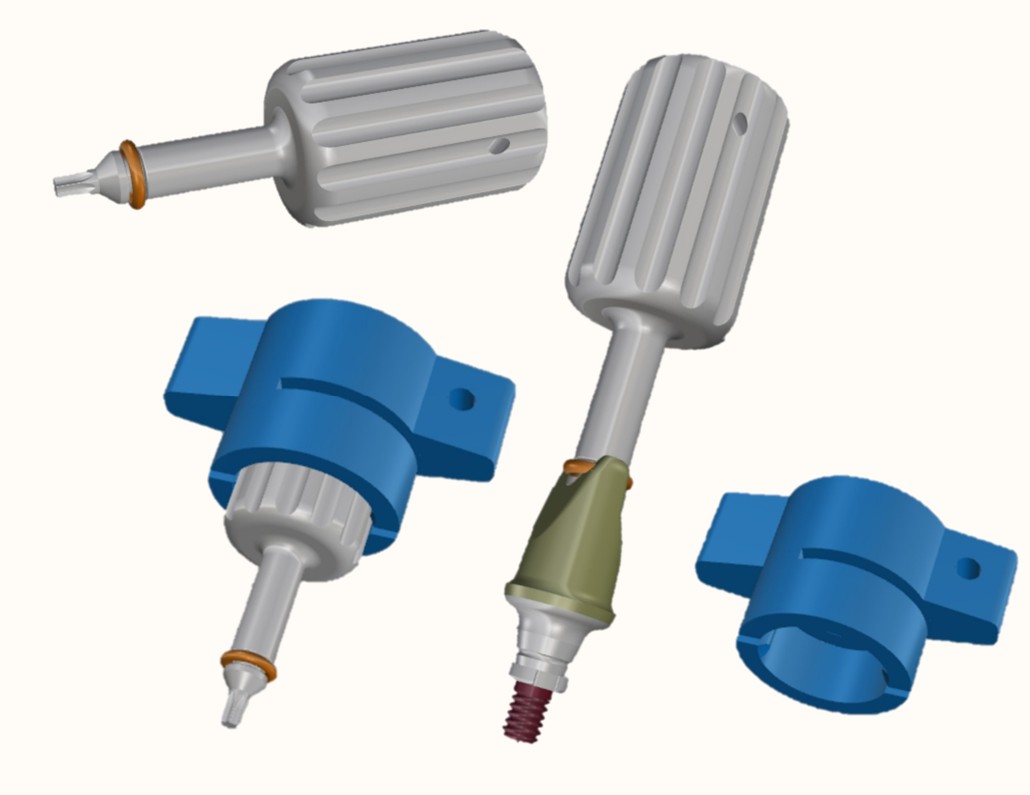

Driver and Torque Controller

• O-ring for no-drop feature.

• Plastic torque driver mounts on driver handle.

• New torque driver used for each case.

• Wings skip at 35 Ncm.

• Wings do not skip during counter turns.

• O-ring for no-drop feature.

• Plastic torque driver mounts on driver handle.

• New torque driver used for each case.

• Wings skip at 35 Ncm.

• Wings do not skip during counter turns.

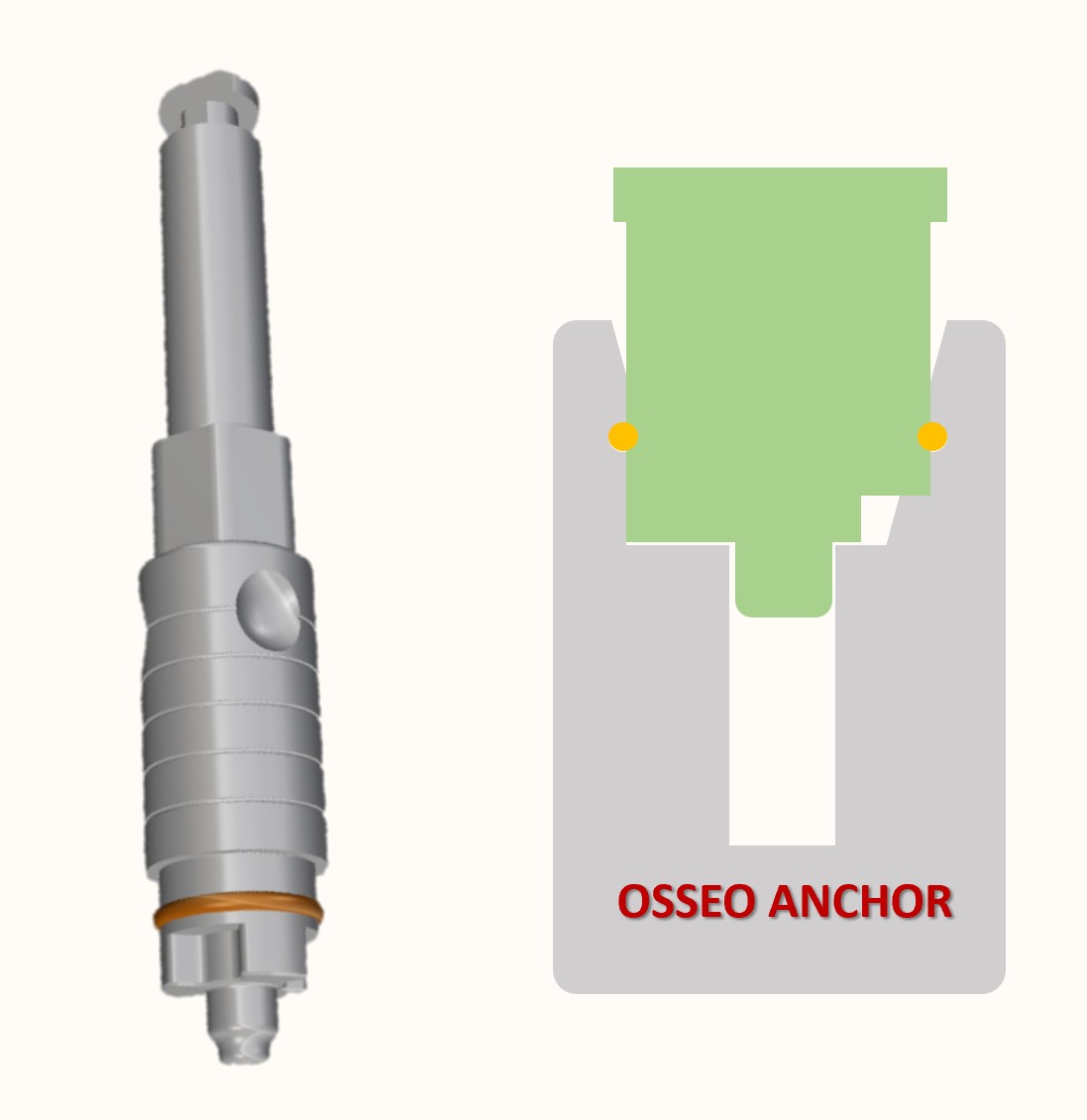

Laboratory Platform

• All prosthetic interfaces are protected by a titanium sleeve.

• All laboratory steps are performed with the protective sleeve.

• The sleeve is retained by a central O-ring.

• The 2 external O-rings are used as dust seals.

• The platforms are placed in the casts with a transfer post.

• The platforms are bonded to 3D printed models.

• The sleeve is kept until the prosthetic delivery.

• All prosthetic interfaces are protected by a titanium sleeve.

• All laboratory steps are performed with the protective sleeve.

• The sleeve is retained by a central O-ring.

• The 2 external O-rings are used as dust seals.

• The platforms are placed in the casts with a transfer post.

• The platforms are bonded to 3D printed models.

• The sleeve is kept until the prosthetic delivery.

Titanium 3D Printed Abutments

• This technology is not possible without the protection of a sleeve.

• The base is fixed flush on the printer bed.

• 200 abutments can be printed simultaneously.

• A thin layer of ti powder is placed on the printer bed.

• A laser sintering melts the powder to the bases.

• Layers after layers are melted together.

• The excess powder is vacuumed away.

• This technology is not possible without the protection of a sleeve.

• The base is fixed flush on the printer bed.

• 200 abutments can be printed simultaneously.

• A thin layer of ti powder is placed on the printer bed.

• A laser sintering melts the powder to the bases.

• Layers after layers are melted together.

• The excess powder is vacuumed away.

Titanium Milled Abutments

• Dess cylinders are milled in laboratories.

• During the milling, the prosthetic interface is protected by the sleeve.

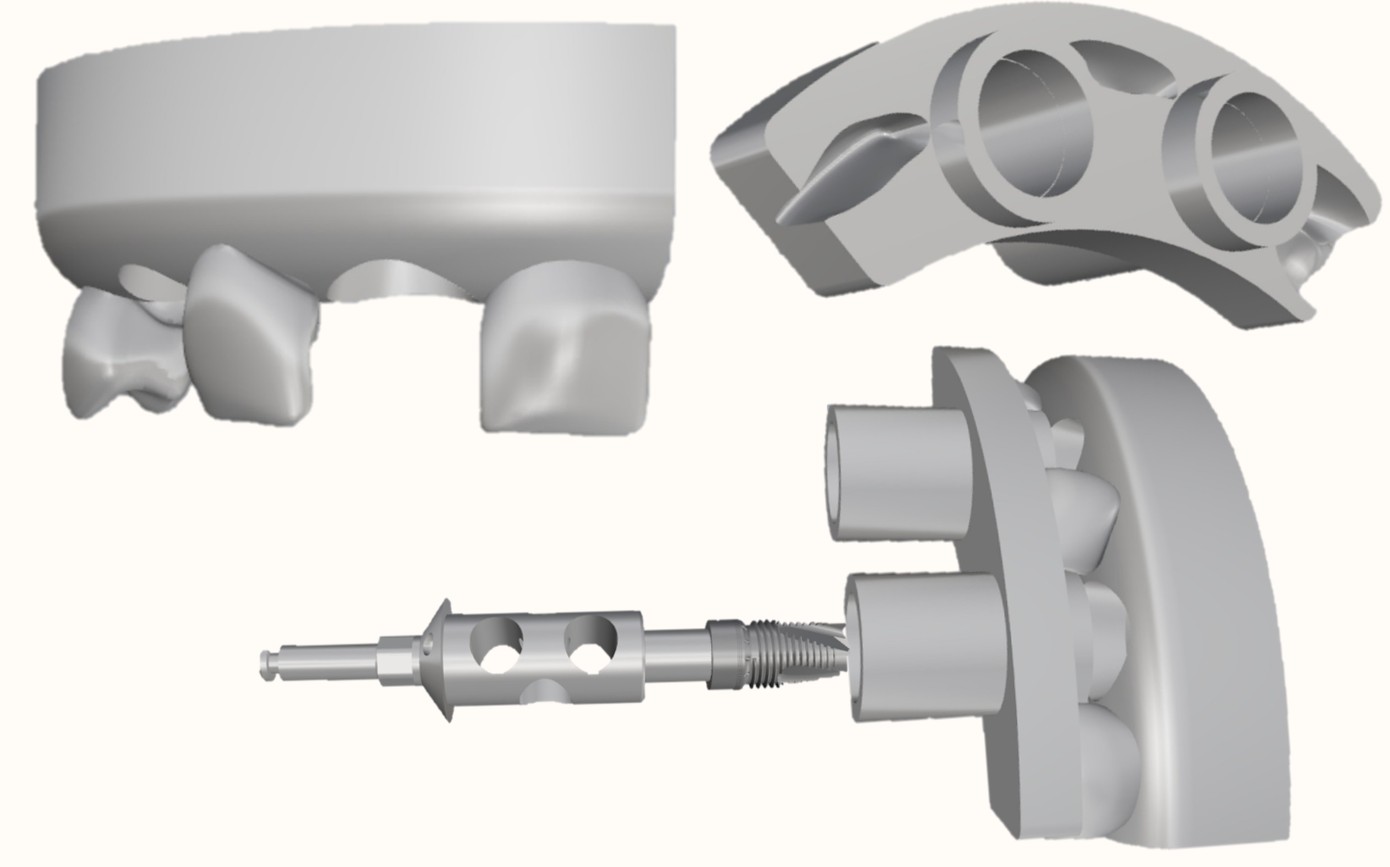

Controlled Surgeries

• Control templates brings additiona precision in implant placement.

• Control templates sit on teeth or mucosa.

• They can be steam sterilized.

• They only assist the dentist with direction and depth of the implant platform.

• The implant length is under total control of the dentist.

• The same control template can be used for every implant length.

• Control templates brings additiona precision in implant placement.

• Control templates sit on teeth or mucosa.

• They can be steam sterilized.

• They only assist the dentist with direction and depth of the implant platform.

• The implant length is under total control of the dentist.

• The same control template can be used for every implant length.

Abutment Extractor

• Used when the abutment can’t be removed by hand.

• Insert the extractor into the abutment chimney.

• Turning the central screw will spread 3 locking balls into the abutment groove.

• When the central screw reaches the bottom of the internal thread, the undamaged abutment will become free.

• Used when the abutment can’t be removed by hand.

• Insert the extractor into the abutment chimney.

• Turning the central screw will spread 3 locking balls into the abutment groove.

• When the central screw reaches the bottom of the internal thread, the undamaged abutment will become free.